WAREHOUSE MANAGEMENT SYSTEM IN NIGERIA

Although the main users of a WMS are warehouse managers, it can be coupled with inventory management, transportation management systems (TMS), customer relationship management (CRM), and enterprise resource planning (ERP). Sales and marketing personnel can look into current statistics on the speed at which sold things are located, gathered, and packaged by researching the WMS. They can also look at a TMS to see the product’s shipping details, including the method, date, and projected arrival time. Performance reports can be created using all of this data.

Where WMS fits in the supply chain

The supply chain, Figure 1, can operate only as quickly, accurately, and efficiently as warehouse processes permit. A WMS plays a vital role in the optimization of supply chain management (SCM) by managing order fulfillment processes, from receiving raw materials to shipping finished goods.

If raw materials are not received properly or parts are misplaced, the supply chain might be slowed or disrupted. WMSes are critical in ensuring these processes work smoothly by tracking inventory and making sure goods are stored and sorted properly, and shipped and tracked accurately.

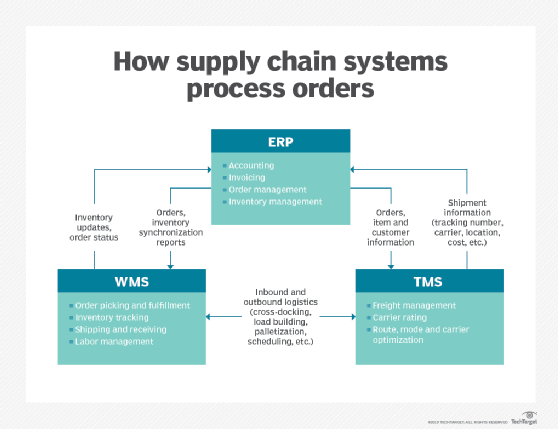

As Figure 2 shows, each of the three main SCM systems has a particular role in managing orders and sharing data with the other two.

By assisting users in managing fulfillment, shipping, and receiving duties in the warehouse or distribution center—such as selecting items from shelves for transportation or storing received goods—the WMS helps users streamline warehouse automation. Its job in inventory is to monitor the data that barcode readers and RFID tags send in, tracking it and updating the ERP system’s inventory management module with the most recent information. The ERP system and the WMS synchronize inventory data through an integration link.

The ERP system handles the accounting and most of the invoicing, order management, and inventory management.

The WMS is where the shipping and receiving processes are managed. It is essentially a repository of detailed information about shipping carriers but is also a transaction-based communication system for planning, executing, and tracking the shipments.

Sometimes, a TMS is integrated with a WMS to better coordinate inbound and outbound logistics tasks that occur at the interface of warehouses and freight shippers. Such tasks include palletization of goods, labor scheduling, yard management, load building, and cross-docking.

Orders typically arrive automatically through order management systems that are connected with TMS or ERP. Additionally, the ERP system outputs the order data required by the TMS to plan and carry out shipments. Data from the ERP system offers comprehensive information about things in addition to fundamental details like the customer’s name and address, ensuring that the correct products are dispatched. The tracking number, carrier name, and other shipment details—details that the ERP system needs for order management and accounting—are returned by the TMS. A module that helps inform consumers of the progress of their orders may also get shipment information.

Types of Warehouse Management Systems

WMSes come in a variety of types and implementation methods. The type typically depends on the size and nature of the organization. Four types of WMSes are listed below:

- Standalone systems.

- WMS modules in SCM systems.

- WMS modules in ERP systems.

- Cloud-based WMS.

WMSes can also vary widely in complexity. Some small organizations might rely on simple hard-copy documents or spreadsheet files, but most larger organizations use complex WMS software.

Who uses warehouse management system technology?

Numerous vendors offer WMS product versions that can expand to different organizational sizes, and some WMS installations are specifically tailored for the size of the company. While some businesses construct their own WMS from the ground up, it is becoming more typical to deploy a WMS from a reputable provider, particularly one that offers cloud services.

It is also possible to customize or modify a WMS to meet the unique needs of the company. A WMS used by an online seller might not perform the same tasks as one used by a physical retailer. Additionally, a WMS may be specifically created or customized for the kinds of products that the company sells. For instance, the requirements for a sporting goods business and a grocery chain would differ.

As depicted in Figure 3, WMSes play a vital role in SCM by ensuring efficient and cost-effective movement of goods and materials through warehouses. A WMS handles the functions that enable these movements, including inventory tracking, picking, receiving, and storage.

Features of warehouse management systems

Many features shown in Figure 2 are common to WMS software products. They address the following:

- Warehouse design. This enables organizations to customize workflow and pick logic to ensure the warehouse is designed for optimized inventory allocation and movement. The WMS establishes bin slotting that maximizes storage space and accounts for variances in seasonal inventory.

- Inventory tracking. This accommodates advanced tracking and automatic identification and data capture (AIDC) systems, including RFID and barcode scanners to ensure goods can be found easily when they need to move.

- Receiving and storage. This facilitates inventory storage and retrieval, often with pick-to-light or pick-to-voice technology to help warehouse workers locate goods.

- Picking and packing goods. This includes zone picking, wave picking, and batch picking. Warehouse workers can also use lot zoning and task interleaving functions to guide the pick-and-pack tasks most efficiently.

- Shipping. This lets the WMS send bills of lading ahead of the shipment, generate packing lists and invoices for the shipment, and send advance shipment notifications to recipients.

- Labor management. This helps warehouse managers monitor workers’ performance by using key performance indicators (KPIs) that indicate when workers perform above or below standards.

- Yard and dock management. This assists truck drivers coming into a warehouse to find the right loading docks. A more complex use of yard and dock management enables cross-docking and other functions of inbound and outbound logistics.

- Reporting. This helps managers analyze the performance of warehouse operations and find areas to improve.

Cloud-based warehouse management system

WMSes, along with other enterprise systems such as ERPs, began as systems that were run on an organization’s on-premises servers. This model has been transitioning to cloud-based WMSes, which are flourishing as organizations realize the benefits of running systems in the cloud.

With a cloud-based WMS, the WMS vendor or a cloud service provider hosts and manages the software. Non-cloud managed service providers (MSPs) might also support WMSes. This takes the burden of installing, managing, and upgrading the system off the organization’s IT department.

Small or medium-sized businesses (SMBs) like the ease of installation and lower costs that cloud-based WMSs provide. Larger enterprises often deploy on-premises WMS because they need highly customized systems that meet the requirements of their specific industry and they have the resources to manage the IT requirements. These systems might support specialized requirements, e.g., a short-term unique application, such as housing hazardous chemicals, which a cloud-based provider can implement quickly if needed.

Pros of cloud-based warehouse management systems

The benefits of a cloud-based WMS include the following:

- Faster implementation. Traditional on-premises WMSes can typically take months to implement, while cloud-based WMS deployments can be completed in weeks, depending on the complexity. This means that organizations have a faster path to a positive ROI and can take advantage of the cloud WMS capabilities sooner, which is a huge benefit in today’s fast-paced economy.

- Fewer upgrade hassles. In the software-as-a-service (SaaS) deployment model for cloud-based WMS, vendors handle updates and configuration changes with regularly scheduled upgrades and patches. Being on the latest version of the software and associated patches means organizations spend minimal time and resources managing upgrades.

- Lower costs. Cloud-based WMSes cost less because they do not require hardware, software installation, and IT administrators to manage them. Customizations or modifications, which can be costly for on-premises systems, are vendor-managed with client approval. Upgrades to on-premises systems can also be expensive if they involve reinstalling and reconfiguring the software and upgrading the hardware.

- Scalability. Cloud-based WMSes can be scaled quickly as organizations grow and supply chains become more complex. They are more flexible and can be reconfigured as business requirements or market conditions change.

Cons of cloud-based warehouse management system

Drawbacks of a cloud-based WMS include:

- Long-term costs. While cloud-based WMSes often have lower upfront costs than on-premises systems, paying for licenses on a monthly or annual basis might be more expensive in the long run. Organizations might also incur additional costs for implementing new modules or premium support packages.

- Customization. Costs for customizing SaaS WMS software might be prohibitive, making it less suitable for organizations that need to modify the software to meet their specific processes or industry requirements.

- Updates and patching. Cloud-based WMSes are usually updated and patched regularly. While this ensures that systems are always up to date, it might require that customers change processes periodically to keep up with the new software, and users might need retraining if the changes are significant.

All of the major WMS vendors (IBM, Microsoft, Oracle, and SAP) offer a variety of deployment options, including cloud-based systems. WMS vendors that are primarily cloud-based or cloud-only include Fishbowl, HighJump, and SnapFulfil.

Warehouse management system benefits

WMS implementation and operation can be costly and difficult, however there are many advantages for enterprises that outweigh these expenses.

A WMS can help a company lower labor expenses, increase the accuracy of its inventory, increase flexibility and responsiveness, decrease errors in the picking and shipping of goods, and enhance customer service. With the use of real-time data, modern WMSs enable an organization to handle the most recent details on orders, shipments, receipts, and any movement of commodities.

WMS and IoT

Organizations can make sure they can create and ship the appropriate number of things, at the right price, to the right place, at the right time, with the use of wirelessly connected products and materials and connected equipment. All these features are now more affordable and widely available thanks to the Internet of Things (IoT).

Products can be routed from the pickup location to the endpoint with the use of IoT data that is integrated into a WMS. Organizations can create supply chains that are pull-based as opposed to push-based with the aid of integration. Pull-based supply chains are driven by consumer demand and can make an organization more adaptable and responsive. Push-based systems are driven by forecasts of long-term demand.

WMS and artificial intelligence

An analysis of current WMS (as well as ERP and TMS) systems reveals a rise in artificial intelligence (AI) capabilities. The functionality of the elements covered in the preceding sections can be significantly improved by this specialist technology. Warehouse managers can benefit from artificial intelligence (AI) through various means, including data collection from other systems like order processing or CRM, product location tracking, location details for parts pickers, packing process tracking, and integration with a transportation management system (TMS) to determine the best shipping arrangements.

Top warehouse management system vendors

Several large enterprise software vendors sell WMSes as standalone products or as modules in comprehensive ERP suites. These include the following:

- IBM.

- Microsoft.

- Oracle.

- SAP.

There are a variety of other prominent WMS vendors who focus on specific industries or company sizes such as SMBs, including the following:

- Aptean.

- ASCTrac.

- Blue Yonder.

- Click Reply.

- Epicor.

- Fishbowl.

- HighJump.

- Infor.

- Manhattan Associates.

- Sage.

- SnapFulfil.

- Softeon.

- Tecsys.

Categories

Tags

You May Also Like

-

-

December 1, 2025

-

-

December 1, 2025

-

-

June 12, 2025